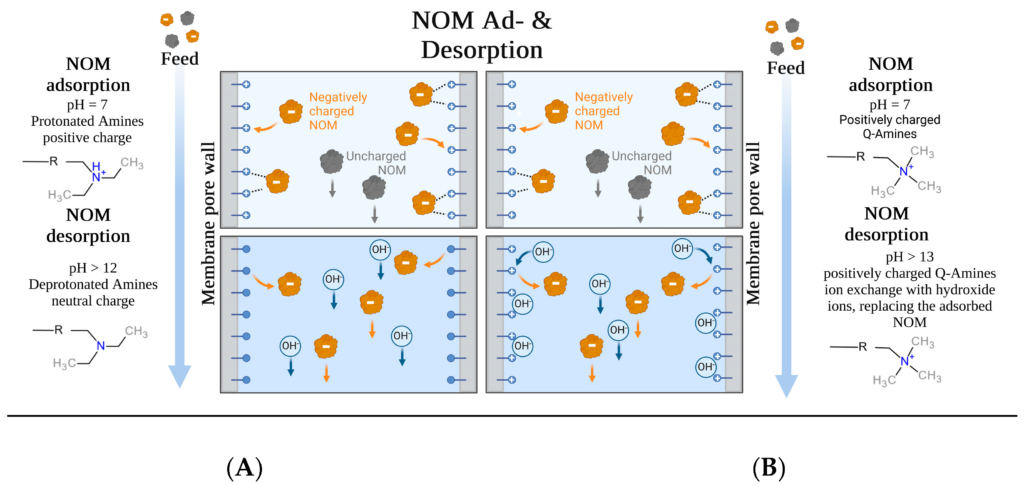

Last month, our colleague Jon Wullenweber and Mathias Ernst at DVGW-TUHH successfully published a new study in MDPI membranes: “Characterizing Macroporous Ion Exchange Membrane Adsorbers for Natural Organic Matter (NOM) Removal—Adsorption and Regeneration Behavior”. The publication demonstrates the potential of using macroporous membrane adsorbers, an adsorptive process in membrane format, for the removal of natural organic matter (NOM), which is the primary precursor of disinfection by-products (DBPs) like trihalomethanes (THMs). One of the key highlights of this process is the remarkably short contact time required, which helps overcome pore diffusion limitations commonly associated with conventional fixed-bed methods. This innovative approach not only enhances efficiency but also sets a solid foundation for the use of membrane adsorbers in the SafeCREW project

The adsorptive membrane process in a flat sheet design allows for the investigation of alternative regeneration methods. In ongoing investigations, these membranes provide the basis for a further advanced process to be explored throughout the project: Application of an electric potential in the closest proximity to the adsorber, further enhancing the efficiency of the regeneration process. Looking ahead, this method shows promise for optimising regeneration using only an electric field, potentially eliminating the need for chemical agents.